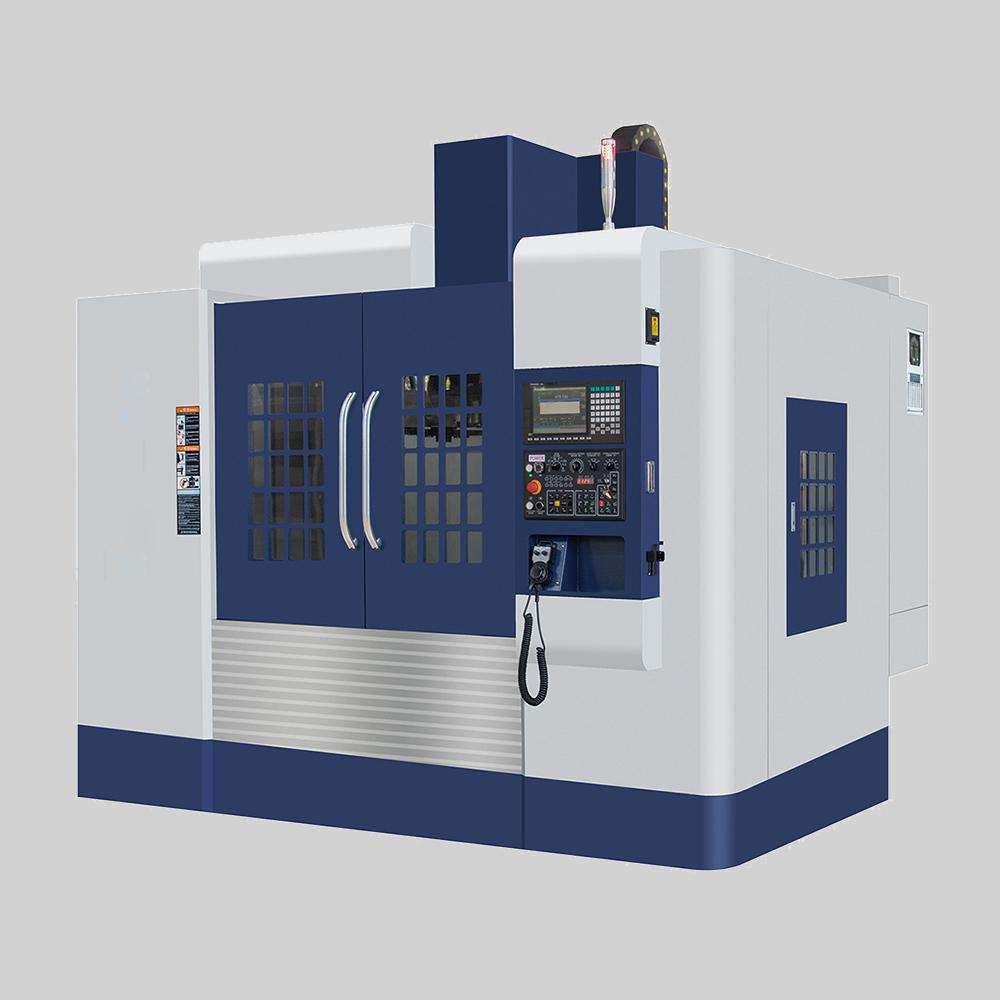

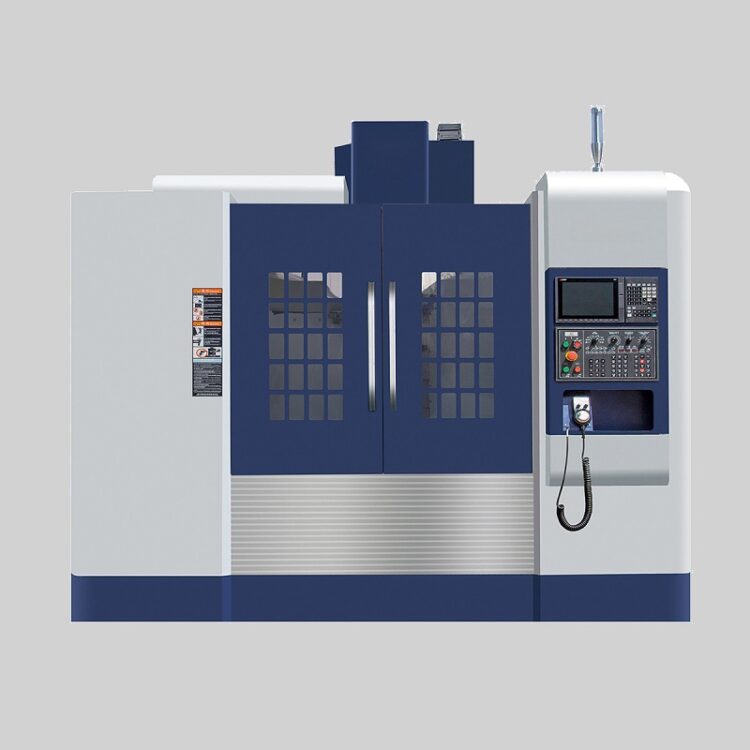

CNC Milling Machine – XK717 / CNC Machine Center is an automatic power mill with CNC (Computer Numerical Controlled) controller, which is used to mill 2D/3D shapes or patterns on various materials. It uses a rotating cylindrical tool, which is able to move along multiple axis, and can create a variety of shapes, slots and holes. In addition, the workpiece is often moved across the milling tool in different directions.

Sanxing Machinery CNC Milling Machine / CNC Machine Center, which is suitable for engraving, carving, milling, cutting and drilling most materials, is widely used in injection mould, ironware mould, metal molds and other molding industries. It is especially designed for batch milling molds, watch, eyeglasses, panel, brand, badge, outside surface’s sleeking, three-dimensional graphics and words. Besides that, it’s easy for this mill to form 2D or 3D relieves on a wide range of materials.

FEATURES OF CNC MILLING MACHINE – XK717/ XH1370

A. Fully Enclosed Cover

B. Controller Integrated

C. Servo Motors

D. Tool Magazine

E. With FANUC control system

F. Automatic Lubrication System

G. HIWIN/PMI Roller Type Linear Guideway

H. HIWIN/PMI Ball Screw

I. FAG Bears

J. Tool Magazine OKADA/Aimach

TECHNICAL DATA OF CNC MILLING MACHINE – XK717 / XH1370

| Main Parameters | Unit | XK717B/XH1370V |

|---|---|---|

| Table | ||

| Table size | mm | 1400×700 |

| Max. Table Load | kg | 800 |

| T-slots(Size*

Space*Numbers) |

mm | 18Tx100x5 |

| Travel | ||

| X axis travel | mm | 1300 |

| Y axis travel | mm | 700 |

| Z axis travel | mm | 650 |

| Distance between

spindle nose and Table top |

mm | 120-770 |

| Spindle | ||

| Spindle taper | BT40 φ150 | |

| Drive Mode | Belt | |

| Spindle Speed range | RPM | 8000/10000 |

| Motor | ||

| X axis rapid feedrate | m/min | 30 |

| Y axis rapid feedrate | m/min | 30 |

| Z axis rapid feedrate | m/min | 30 |

| Ball Screw | ||

| X axis ball screw | mm | φ40xP10 |

| Y axis ball screw | mm | φ40xP10 |

| Z axis ball screw | mm | φ50xP10 |

| Linear Guide Rail | ||

| X axis Linear guide

rail Width/Numbers |

45(2 Rails 6 Slide blocks) | |

| Y axis Linear guide

rail Width/Numbers |

45(4 Rails 8 Slide blocks) | |

| Z axis Linear guide

rail Width/Numbers |

55(2 Rails 6 Slide blocks) | |

| Feed | ||

| Spindle Motor Power | KW | 11-15 |

| X/Y/Z axis Motors Power | KW | 2003/3/3 |

| ATC | ||

| Tool Storage Capacity | T | 24 |

| Max Tool Outer diameter | mm | 80 |

| Max Rinku Tool Diameter | mm | 120 |

| Max Tool Length | mm | 200 |

| Max Tool Weight | kg | 8 |

| Tool change time | sec | 2 |

| Accuracy | ||

| Positioning | mm | 0.003/300 |

| Repeatability | mm | 0.003/300 |

| Machine Weight/Area cover size | ||

| Machine Size | mm | 3650x2750x2850 |

| Machine Net Weight | kg | 10000 |

PRODUCT DETAILS OF CNC MILLING MACHINE

OPTIONAL

1. Model: From XK7135 to XK719(XH1890)

2. Different Control System Optional

3. Rotation worktable 4th-Axis Optional

4. Different Speed of Spindle Optional

5. Different Type of Tool Magazine Optional

6. Tool Capacity of Tool Magazine Optional

DELIVERY TIME

- 30~45 days after order confirmation

WARRANTY

- One year

During warranty period, we can provide free parts and components that are not damaged due to improper operation (consumables are excluded). Out of warranty period, we will supply our best service to you as usual, if you have any question.

1. Offer technical support online service.

2. Technical files service & on-site training service provided.

3. Offer machine operation video.

4. Spare parts replacement and repair service provided.

5. All questions will be replied within 24 hours.

FAQ

Q: Are you a manufacturer or trading company?

A: We are the professional manufacturer of cnc wire cut edm machine, which have been in the industry around 30 years.

Q: Can you provide training and maintenance?

A: Yes. In order to make your production more efficient, before the delivery, you can send someone to my company for free professional operation training.

Q: What information will you need to make the proposal?

A: Worktable size, worktable travel, max table loading weight, type of tool magazine and your special requirement.