Sanxing Brand CNC Die Sinking EDM, can be considered as one kind of CNC Die Sinking EDM Machine or CNC EDM Machine, is mainly used in the complex mold cavity, especially for that not easy to polish the complex surface precision processing. It can eliminate the manual polishing process, improve the service performance of parts, and shorten the mold manufacturing cycle.

CNC Sinker EDM machine refers to a machine that can realize the discharge machining or the multi-axis dynamic discharge machining. The mechanical structure of the sinker EDM machine is firm and strong with a practical function. Sinker EDM machine is perfect machining applied in the tooling industry for the EDM die sinker can produce molds with high precision and smoothness. EDM die sinking machine is wildly used in any industry which requires a precision finish. Due to the hard property of metal, the spark erosion machine only comes out with the electrical sparks rather than touches the metal directly. Sanxing Machinery has various types of sinker EDM machines for you to choose.

FEATURES OF CNC DIE SINKING EDM – BM100

A. Three-Axis Linkage

B. C-Structure Design

C. Servo Motor for Three-Axis

D. Linear Guideway from PMI/ HIWIN

E. Ball Screw from PMI/ HIWIN

TECHNICAL DATA OF CNC DIE SINKING EDM MACHINE – BM100

| Mechanical specifications | Unit | BM100 |

|---|---|---|

| Table size (length x width) | mm | 1250×800 |

| X axis Travel | mm | 1000 |

| Y axis Travel | mm | 600 |

| Z axis Travel | mm | 450 |

| The internal dimensions of processing tank | mm | 2000x1300x700 |

| Max. electrode weight | kg | 150 |

| Table Loading weight | kg | 3500 |

| Min. Distance from electrode plate to working table | mm | 550 |

| Max. Distance from electrode plate to working table | mm | 1000 |

| Total input power | KVA | 10 |

| Input power | V | 380 |

| Max. machining current | A | 50 |

| The number of control axis | Three axis three linkage |

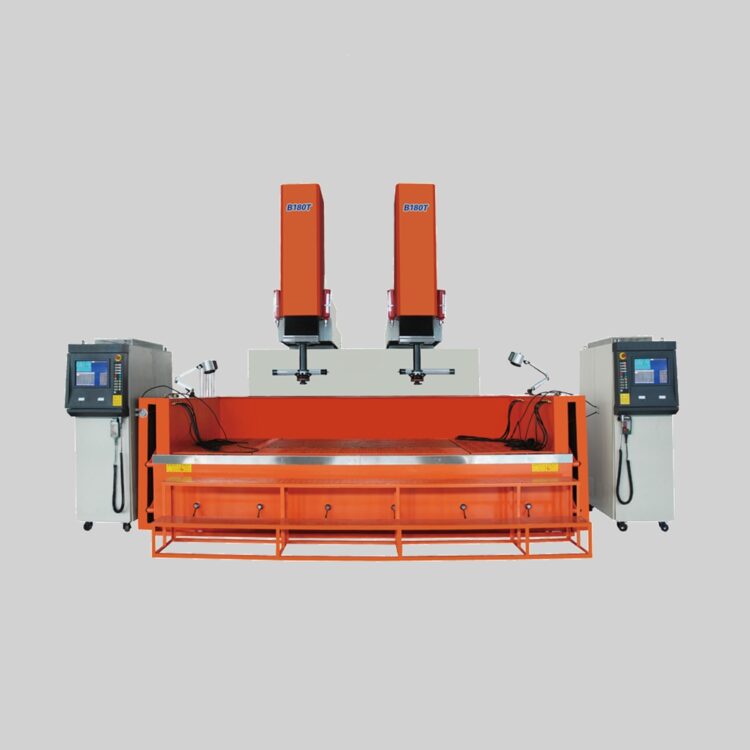

MIRROR SPARK EDM MACHINE

OPTIONAL

1. Model: From B30 To BM180T

2. Magnetic Worktable Optional

3. Orbital Head Optional

4. Different Working Current Optional

DELIVERY TIME

- 15 days after order confirmation

WARRANTY

- One year

During warranty period, we can provide free parts and components that are not damaged due to improper operation (consumables are excluded). Out of warranty period, we will supply our best service to you as usual, if you have any question.

1. Offer technical support online service.

2. Technical files service & on-site training service provided.

3. Offer machine operation video.

4. Spare parts replacement and repair service provided.

5. All questions will be replied within 24 hours.

FAQ

Q: Are you a manufacturer or trading company?

A: We are the professional manufacturer of cnc wire cut edm machine, which have been in the industry around 30 years.

Q: Can you provide training and maintenance?

A: Yes. In order to make your production more efficient, before the delivery, you can send someone to my company for free professional operation training.

Q: What information will you need to make the proposal?

A: Worktable size, worktable travel, surface finish, machining accuracy, and your special requirement.