Sanxing Machinery ZNC700 Die Sinking EDM / Sinker EDM Machine is used for cavity forming. It utilizes conductive material (copper, graphite, steel) as electrode to process workpiece (conductive material) by spark erosion. ZNC EDM Sinker has X and Y-axis manual control, and Z-axis automatic control. It can do one single job after manually set position, and job setting is also manual. Ideal for molds and spare parts manufacturing industries, ZNC die sinking EDM machine for sale by Sanxing Machinery is your best choice for die sinking operation!

Jiangsu Sanxing Machinery Sinker EDM Machine ZNC700 is featured in strong functions, convenient and reliable operation, of fairly good rigidity, running placidly, of good controllability, suitable to process conductive metal moulds, complicated metal parts and templates with high precision, high toughness and difficult processing. EDM process has become the important part in the field of mechanical manufacture. They are widely used in the fields of moulds, and electronic instruments, precision mechanical process, automobile parts, military, etc.

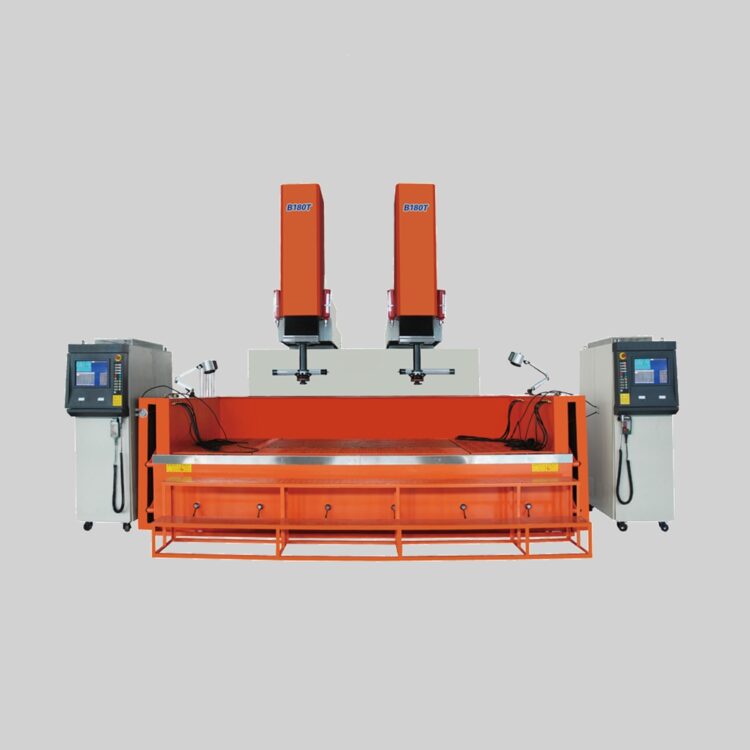

FEATURES OF DIE SINKING EDM MACHINE – ZNC700

A. Taiwan C-Tek Controller

B. Three axes DROs

C. High accuracy X, Y, Z three axes C3 grade Taiwan-made ball screw

D. Servo Motor for Z-Axis

E. Max. Working Current: 50A/60A

F. Surface Finishing:Ra 0.2~0.8um

TECHNICAL DATA OF DIE SINKING EDM MACHINE – ZNC700

| Mechanical specifications | Unit | ZNC700 | |

|---|---|---|---|

| Table size(length x width) | mm | 1200×650 | |

| Working slot (XxYxZ) | mm | 1950x1050x650 | |

| Maximum oil level (from table) | mm | ≤470 | |

| Longitudinal travel | mm | 700 | |

| Lateral travel | mm | 600 | |

| Vertical travel | Spindle | mm | 300 |

| Auxiliary travel | mm | 350 | |

| Maximum distance from worktable to electrode head | mm | ≤950 | |

| Maximum electrode Weight | KGS | ≤200 | |

| Maximum workpiece Weight | KGS | ≤2000 | |

| Machine weight | KGS | 3500 | |

| Packing Size | mm | 2400x2010x2740 | |

SINKER EDM MACHINE – ZNC TYPE

OPTIONAL

1. Model: From EDM350 To EDM700

2. Magnetic Worktable Optional

3. Orbital Head Optional

4. Different Working Current Optional

DELIVERY TIME

- 15 days after order confirmation

WARRANTY

- One year

During warranty period, we can provide free parts and components that are not damaged due to improper operation (consumables are excluded). Out of warranty period, we will supply our best service to you as usual, if you have any question.

1. Offer technical support online service.

2. Technical files service & on-site training service provided.

3. Offer machine operation video.

4. Spare parts replacement and repair service provided.

5. All questions will be replied within 24 hours.

FAQ

Q: Are you a manufacturer or trading company?

A: We are the professional manufacturer of cnc wire cut edm machine, which have been in the industry around 30 years.

Q: Can you provide training and maintenance?

A: Yes. In order to make your production more efficient, before the delivery, you can send someone to my company for free professional operation training.

Q: What information will you need to make the proposal?

A: Worktable size, worktable travel, surface finish, machining accuracy, and your special requirement.

Keywords: ZNC Die Sinking EDM Machine, Die Sinking EDM Machine, EDM Machine, Electrical Discharge Machining Machine, ZNC Electrical Discharge Machining Machine, ZNC Spark EDM Machine, Spark EDM Machine, Sinker EDM…